Personally, I was never a fan of electric vehicles until a certain point.

At the beginning of October 2023, I had a family get-together with some relatives I’d only seen a few times during the year. It was a whole Sunday, from 10 in the morning until 10 at night. In the course of the afternoon, in conversation with one of the relatives, the subject of cars came up, and as is usual in male-to-male conversation, I mentioned the study I’m doing for my dissertation, which involves electric vehicles. As a result of the conversation, this relative showed me his car and let me drive it. The car in question is a BMW I4 M50, with 544bhp. As you can imagine, my opinion changed immediately after driving it for a while. Acceleration, handling, braking, the car in question had everything a gear head could want, except noise and vibrations, perhaps the most important thing.

At the end I asked him how his experience was going, where the questions were more geared towards the subjects of my study, such as the distance he travelled per week, the charging time and the charging stations he used, questions on these topics. He told me how much he loved the car, and questions about how charging the batteries was extremely practical, quick and cheap. I was surprised.

However, I’ve always had a concern about electric vehicles and my family member’s experience was in line with it, which was related to charging cycles and battery life. It’s no news that the more cycles a battery has, the shorter its life will be. In my relative’s case, as he bought the car new and as BMW offers a 10-year battery guarantee, he’s not worried. However, as an environmental engineer, I am concerned about the situation, because I always want to achieve the lowest consumption of raw materials, especially a raw material that is being increasingly mined and exploited, such as lithium.

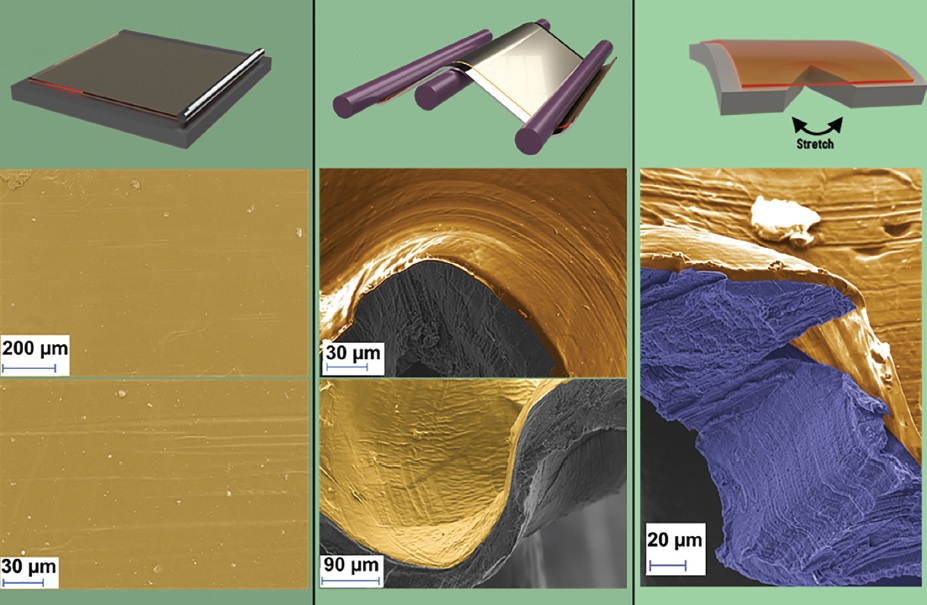

To my delight, I have learnt of a promising study on the same subject that has come up with a new design for a lithium-sulphur battery, in which the lithium foil is coated with a nanoporous polymer. It’s a lot to swallow, but stick with me and I’ll explain.

Firstly, the study originates from Monash University in Melbourne, Australia. It was conducted by PhD student Declan McNamara, Professor Matthew Hill and Professor Mainak Majumber from Monash Engineering together with Dr Makhdokht Shaibani from RMIT University.

Figure 3 – Research article and Monash University in Melbourne, Australia.

Lithium-sulphur batteries are not completely free of limitations. As they have lithium anions (negative electron) and sulphur cations (positive electron) with a separation layer, when the battery charges and discharges, large quantities of lithium and sulphur react with each other, putting the lithium metal under great strain. Add the reality that lithium is a mineral that stores a lot of energy, and that energy can be lost in side reactions if the battery is faulty, and it can become a recipe for disaster.

Felizmente, este revestimento fino de polímero sobre o lítio vem melhorar significativamente o número de vezes que a bateria pode ser submetida a ciclos de carregamento e descarregamento, e assim prevenir isto.

The polymer contains tiny holes of less than a nanometre (a billionth of a metre) that allow the lithium ions to move freely, blocking other chemicals that would attack the lithium. The coating also acts as a support for the lithium and helps it to charge and discharge repeatedly.

Last but certainly not least, this type of battery has the great advantage of not incorporating nickel or cobalt minerals into its constitution. This removes the need for minerals that have a significant environmental and social cost.

So this new design uses less lithium, has more energy per unit volume, lasts longer and will be half the price of lithium-ion batteries. What more could you wish for?

As I said at the beginning, I’ve never been a big fan of electric vehicles. I’ve always favoured internal combustion vehicles because of the ideology of the driving experience and everything that goes with it, from the vibrations, the noise, the delay in power delivery and so on. Looking back now, I realise that I had that opinion simply because I didn’t know the facts and had never ridden in an electric vehicle.

We are all influenced by other people to some extent. It’s up to each of us to consider whether that person has our best interests at heart. I can say that one great influencer I had who changed my mind was Miguel Stiwell d’andrande, the CEO of the EDP group.

Many high-ranking people try to influence people to consume a certain product only with the company’s own interests in mind. I never got that feeling with him. He has never denied the negative aspects and has never leaned towards the positive aspects of technologies. He always takes an explanatory stance on the situation, and tries to deliver the facts to his audience.

I hope that with this article, I have not only gained knowledge through my research into battery issues, but I also hope to have given you an insight into the future of electric mobility. In the beginning, battery technology in electric vehicles was unreliable and out of step with combustion engines. However, with each passing year the technology will become better and better, and it will become an option for the population that cannot be denied.

With this in mind, I would like to quote the CEO of EDP, Miguel Stiwell d’andrade.

“Whenever there’s a change, whenever there’s a disruption in the sectors, there’ll be winners and there’ll be losers. We clearly see ourselves as a winner.”

— Miguel Stiwell d’andrade

Leave a comment